Free Up Your Progressive Shocks

For a Buttery Ride

Mr. Detail VROC 16664

![]()

Many of you have replaced your OEM rear shocks with

units from Progressive Suspension. These are some of the best shocks on the

market, their quality of materials and finishes are second to none.

I replaced the shocks on my 2000 Classic 1500 with

Progressive’s 440 units. When I received the shocks they had a handful of

steel bushing sleeves to help you get the right fit, right? Not necessarily and

the reason for this article. Only one set of steel bushing sleeves was the right

diameter to fit the bike mounting studs. These bushing sleeves were shorter than

the width of the rubber bushing. I had to trim the rubber bushing with a razor

knife otherwise when I bolted on the shocks the rubber bushing was being

squeezed to the point that with the nuts and washers properly torqued, the shock

was bound at both pivot ends. I had learned from my RC gas racing days that

shocks, while needing to be properly attached, also need to be free to pivot

when the suspension worked its magic soaking up the bumps and potholes.

Fast

forward to 18 months later and now 65 lbs lighter. The stiff ride was killing

me. I had the shocks set on full soft (no preload) and yet I could feel every

bump like I had struts on the rear. I decided to call Progressive and order the

standard springs. When I changed the shock springs I inspected the hardware as I

took them off and found a groove had been worn on the inside of each of the

chrome flat washers. Apparently the steel sleeves were a bit too long and had

been binding up and cut the grooves.

Fast

forward to 18 months later and now 65 lbs lighter. The stiff ride was killing

me. I had the shocks set on full soft (no preload) and yet I could feel every

bump like I had struts on the rear. I decided to call Progressive and order the

standard springs. When I changed the shock springs I inspected the hardware as I

took them off and found a groove had been worn on the inside of each of the

chrome flat washers. Apparently the steel sleeves were a bit too long and had

been binding up and cut the grooves.

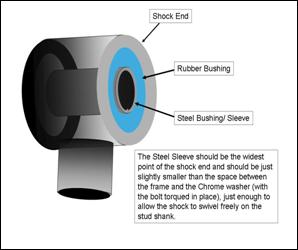

THE FIX: I

bolted the flat washer and lock washer onto their respective studs and using a

caliper, measured the space between the flat washer and the bike frame mounting

boss and in my case it was 0.78”. The sleeve measured 0.784”, just a tick to

long and enough to bind up the shock action. Using a flat mill file clamped to

my work bench I drew each of the bushings over the file till I could fit each of

the bushings between the frame and flat washer that I had left bolted in place.

That done I slid the sleeves into the rubber bushings and test fit each end of

each shock to be sure they would pivot freely with the mounting bolts firmly

torqued in place.

All

I can say is this is the ride quality I was looking for and I wish I had been

more thorough the first time and noticed the slight differences. The ride now is

buttery smooth and the bike much more enjoyable.

All

I can say is this is the ride quality I was looking for and I wish I had been

more thorough the first time and noticed the slight differences. The ride now is

buttery smooth and the bike much more enjoyable.

PLEASE NOTE: The measurements I have indicated are from

my Vulcan Classic. Given manufacturing differences, these measurements may be

different on your Vulcan. The object is to get the best fit and best possible

ride quality for your bike.